MORE

etting up this website, it strikes me that it is as much about people as about boat work. 'Ginger-Dot' runs like a thread through lives, world events, tragedy and to date, efforts and toil to help her through into some sort of future. I do wonder if the world to come will actually value the expensive relics of such different times or is everything old redundant?

When historical research got under way it was in the late 1990's and the digitizing of records not really very far progressed - much was still a matter of transatlantic phone calls and faxes. Now more is available and adding to the history files all the time.

Looking back at the work of an almost total and authentic rebuild I marvel at the dedication and high standards of the men who worked so hard in that dark, cold, cheerless shed through six winters and seven summers. Those who came straight from the IBTC in Lowestoft had been aiming for second careers working on smaller and more rewarding projects. The Whisstocks old shed and the repetitive nature of much of the work was more like working down a coal mine! They remained mostly cheerful - true grit.

Then began a long period of much needed rest and search for more funds. We went in for property development just before the financial crisis of 2008. Not a big success.

Angus, at 70, still managed to repaint the hull twice, standing on a floating 4'x6' platform. Each summer we spend weeks at scraping back and revarnishing the decks.

The huge plastic cover proved a success but too weighty in rough weather for the rather flimsy supporting arches. Much valuable time has been wasted in preserving and strengthening the whole affair. But the cover itself lasted well beyond its intended life of five years. Only in 2015 it was essential to make a new cover and we started by replacing the feeble old arches with a much improved structure. We bought 48mm steel polytunnel arches and then re-bent them all to pattern, upscaled from a model. Also made an internal long wooden spine linking the central four arches. The new cover still awaits until we can have the right conditions to replace the still intact old cover.... watch this space

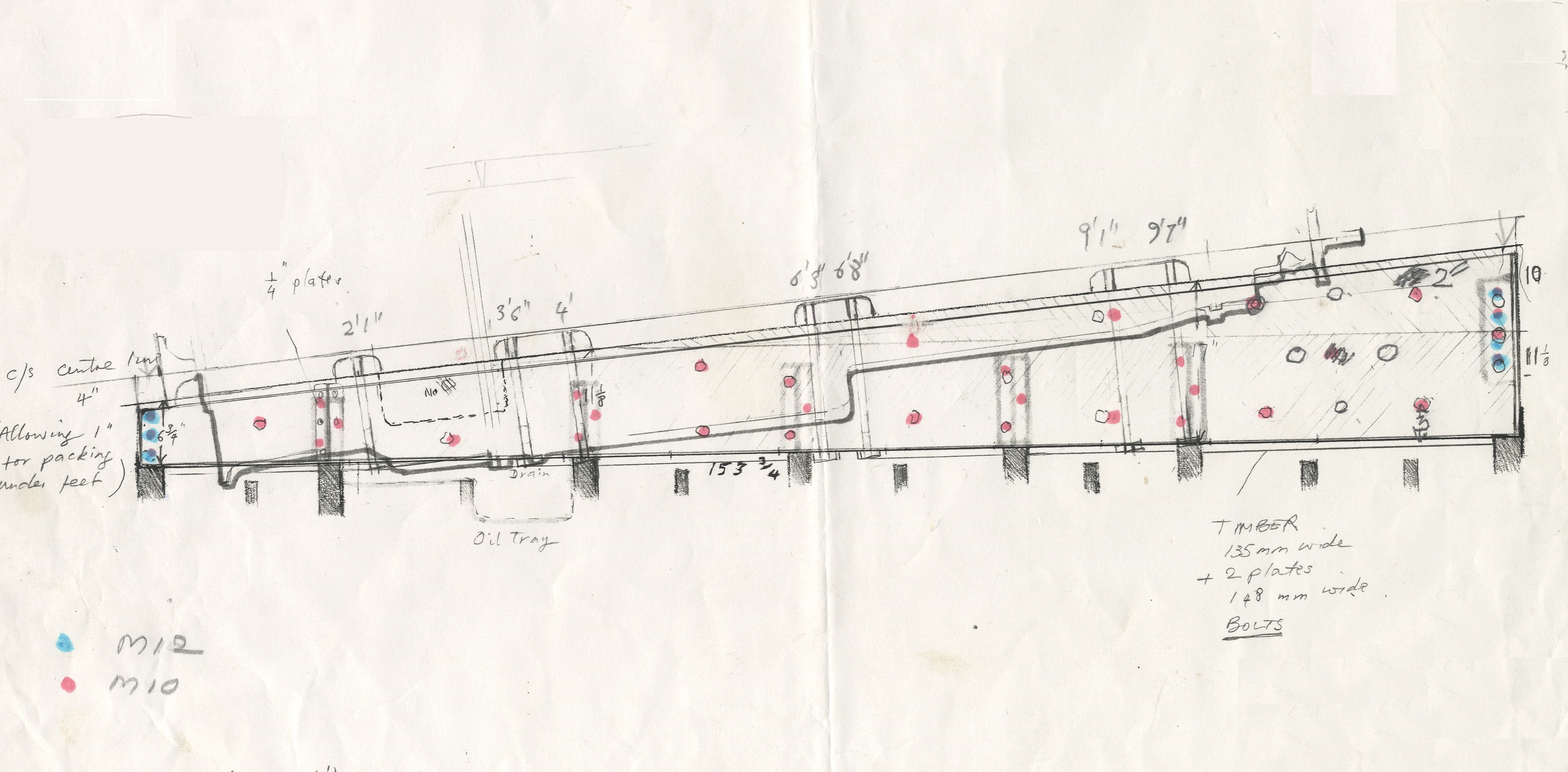

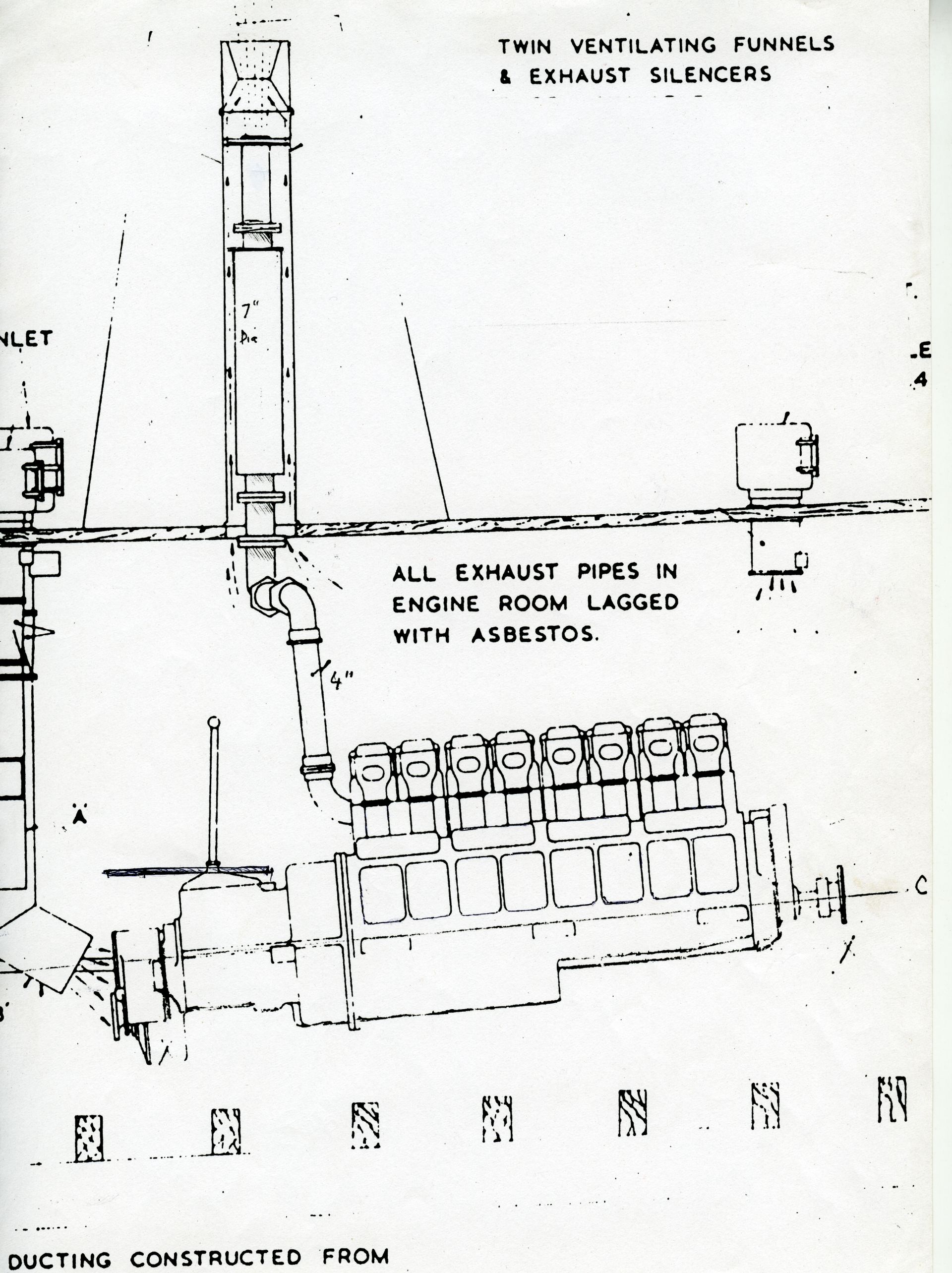

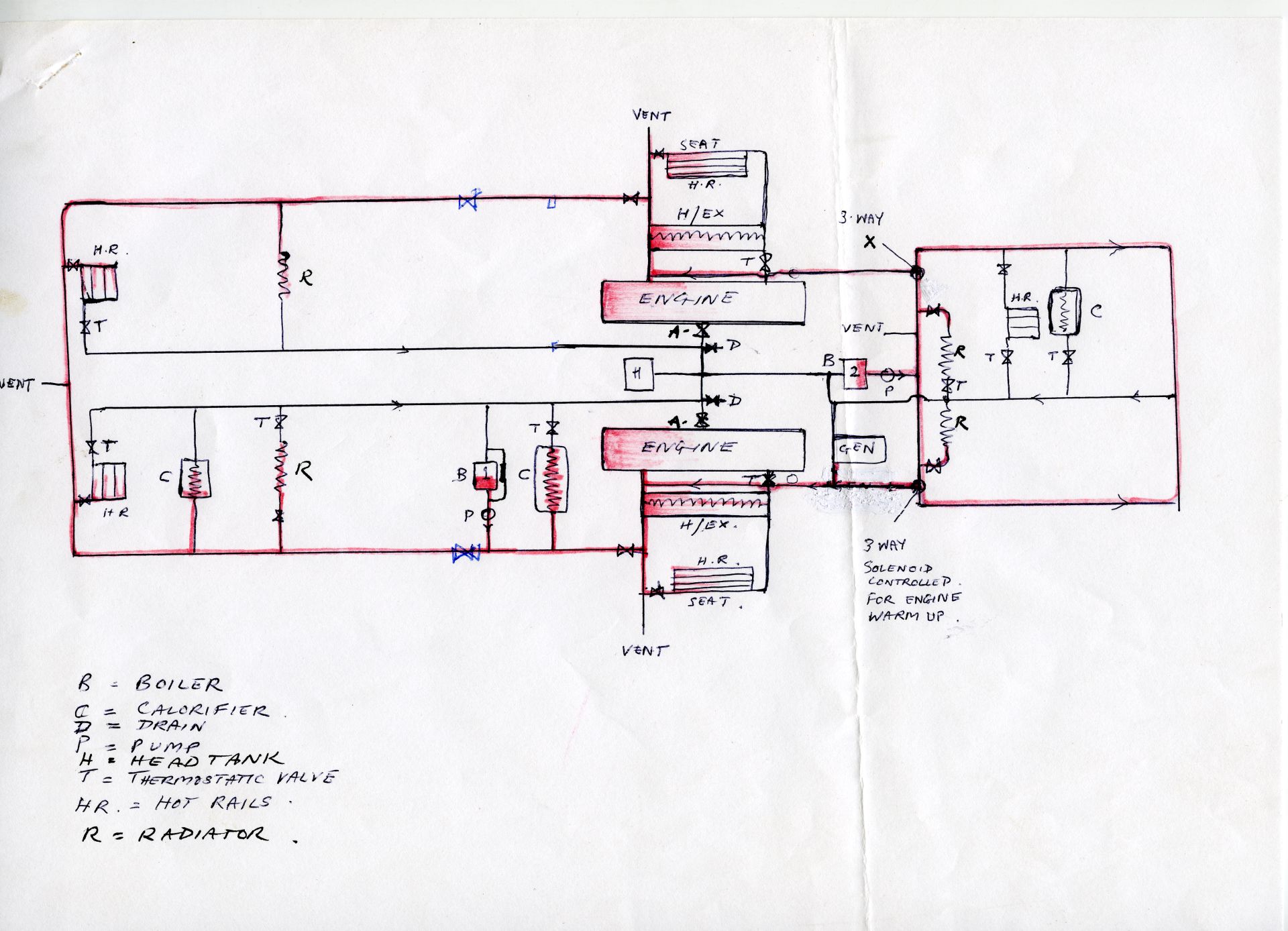

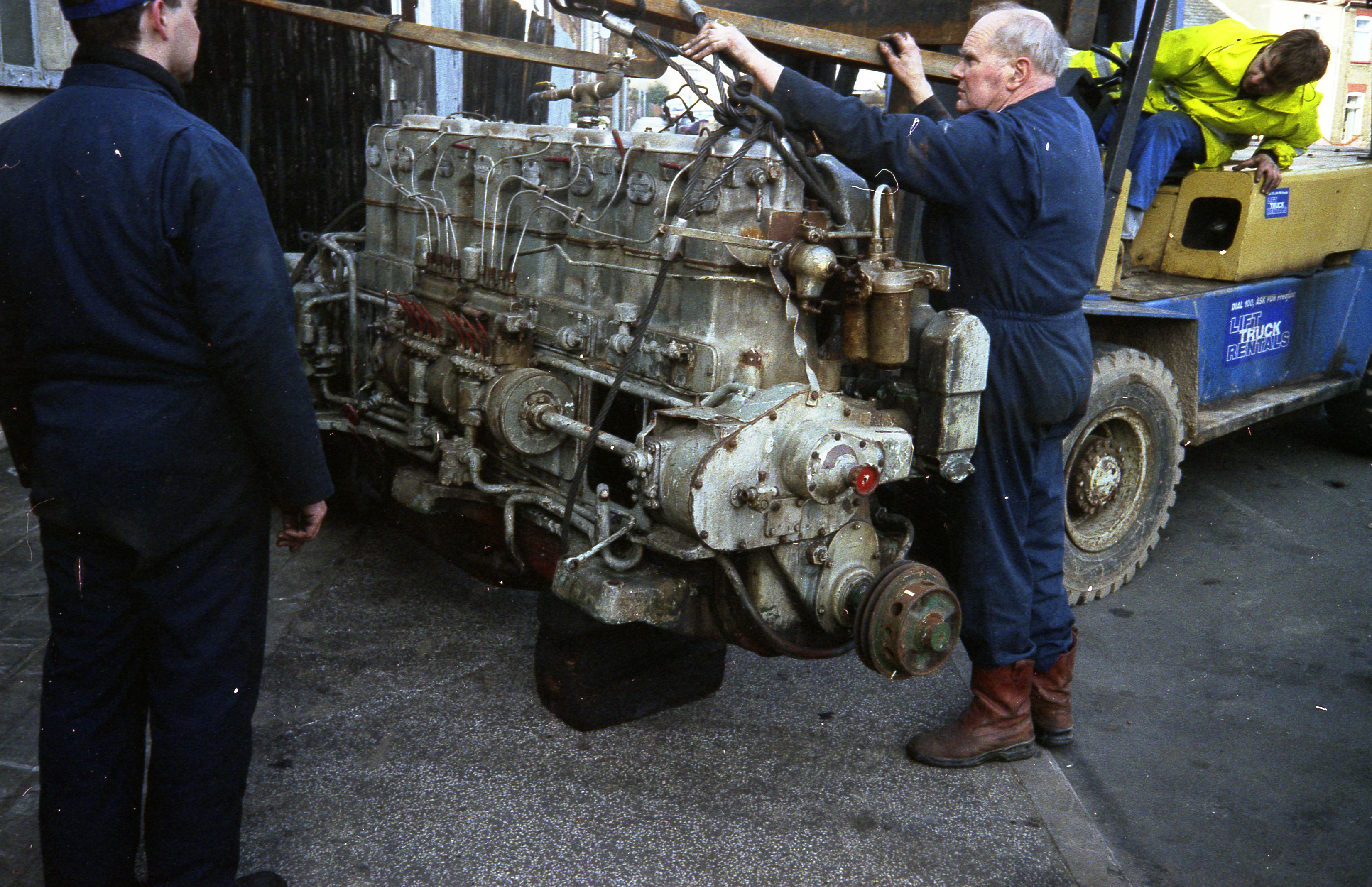

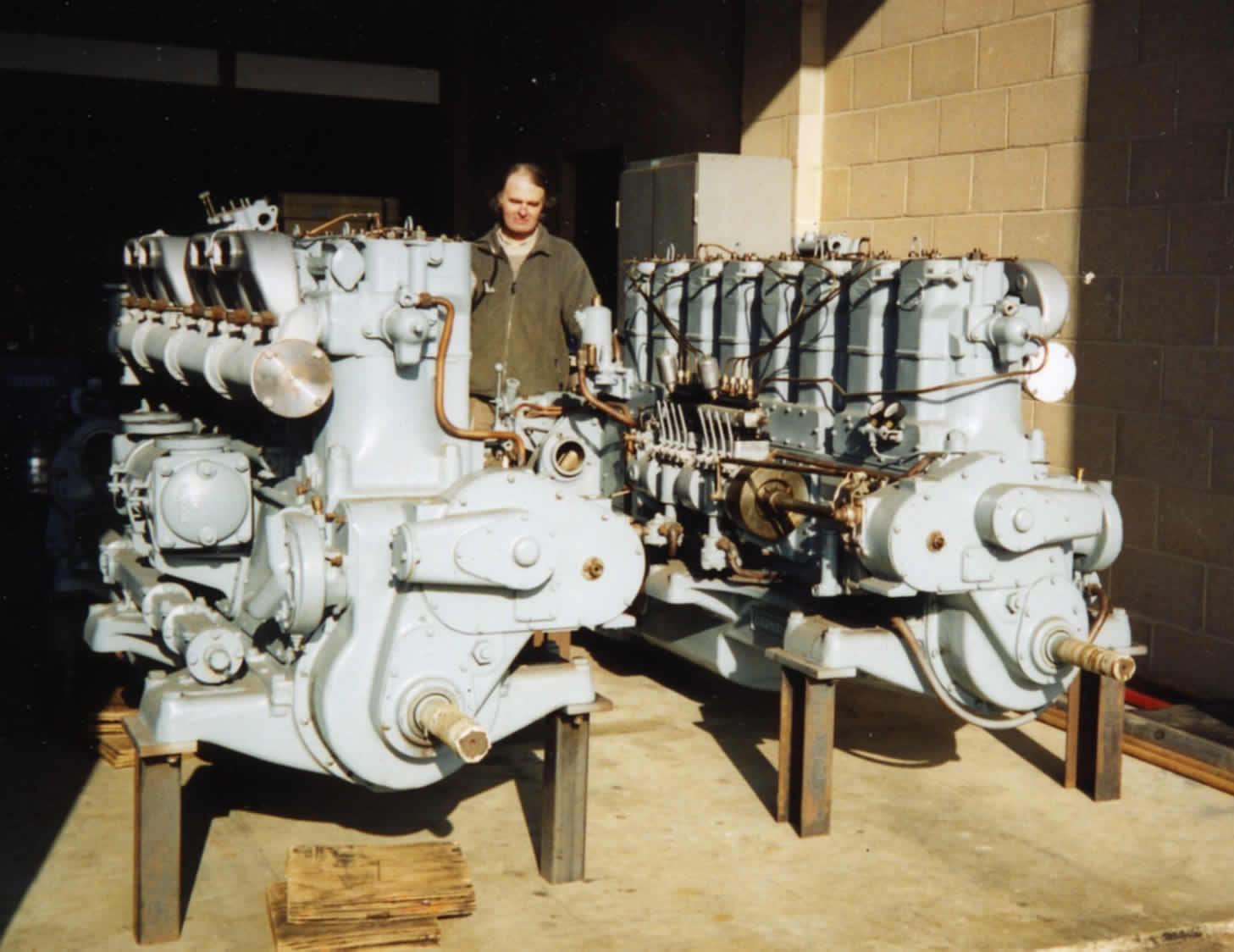

T hey are another whole project. We decided Gardner 8L3's were the ideal replacements in weight, size and power. We explored a pair in a yacht that was close to sinking on the Broads - even looking at them was perilous. They had already 'been under' before. Negotiations were nigh on impossible and that proved very lucky for us. Soon after news came that a marine engineer in Brightlingsea had a handed pair of these engines, which he had removed from the yacht 'Atlantide'.

We contacted Marshall Manthorpe of Metal Coatings in Lowestoft. The firm had been Gardner agents and a long record of keeping the Lowestoft fishing fleet running. Marshall came to inspect the engines. They had been pensioned off due to severe rust in the water cooling areas. Most of the heads bursting and liners very pitted. But in terms of mechanical wear - virtually nothing. 'Atlantide' had been sitting around most of her life....

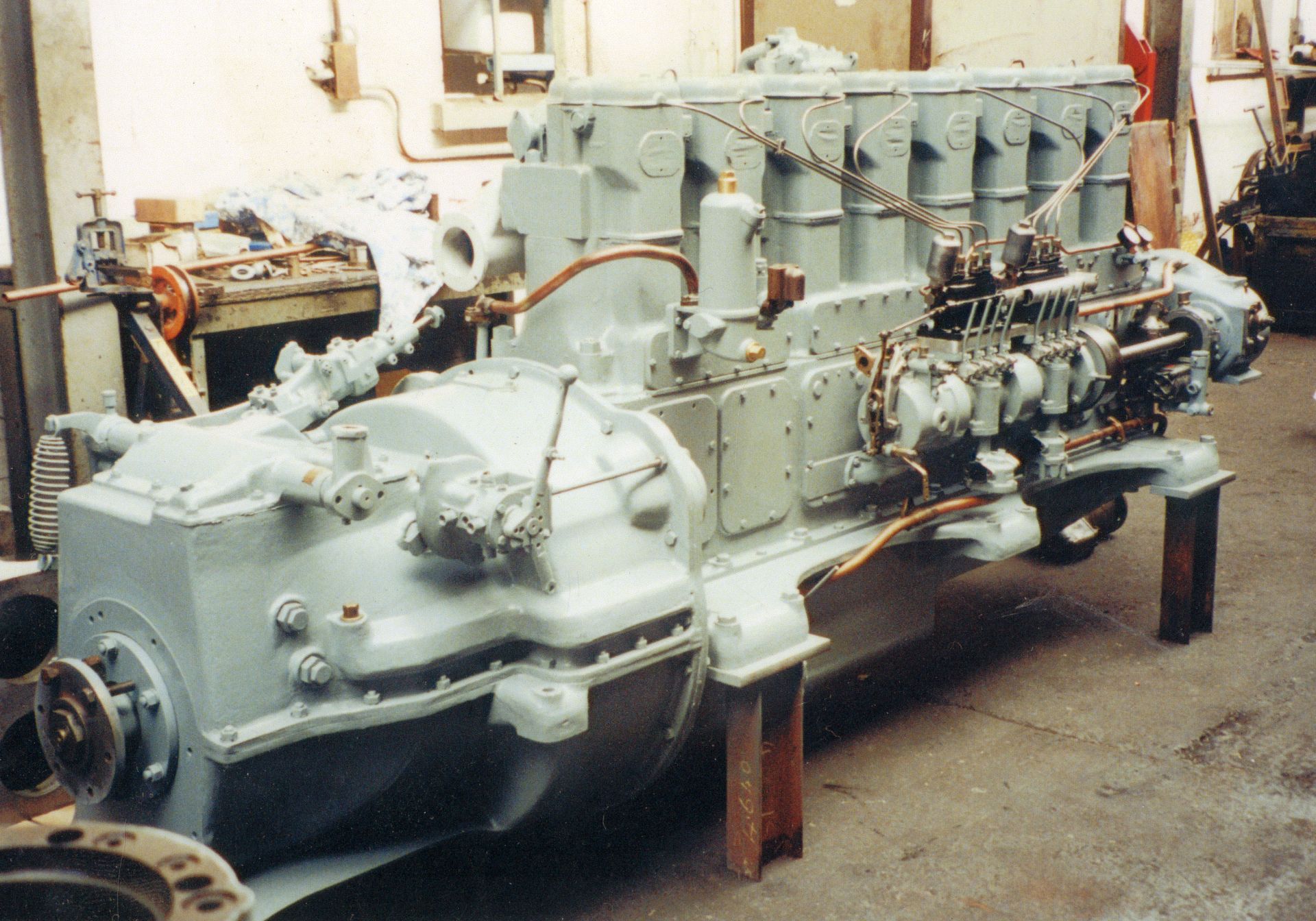

Marshall undertook to restore these engines as a last project - the business on the brink of closure. They had lots of contacts, expertise and spares. My job was to learn about Gardner 8L3's and buy parts. Sixteen new heads were sourced (at some cost..) from South Africa and Australia. New liners and pistons. Fuel pumps overhauled by Paul Gardner and other spares from Gardner dealers in England now all disappeared. We saw the neccessity of indirect cooling (as the 8L3B) and bought new Heat Exchangers and other components to convert our engines. The massive 3UC gearboxes also overhauled.

Marshall's workshops were sold for redevelopment and the engines, almost ready for installation, were moved to Angus's workshop where they remain.

A

surveyor marvelled at the condition of Ginger-Dot's underwater bronze castings. The huge rudder virtually without corrosion as were the shaft brackets. But when we started to clean and buff the golden surface something rather awful appeared. The deeper we polished freckles appeared and then pitting. It seemed that time had almost dissolved the bronze and replated it somehow on the surface leaving seriously depleted metal below, going inside quite a long way. Of course bronze becoming 'carroty' is well known but this was much more deceptive. A skin of good brass had formed there somehow..

Given the work involved, the pragmatic decision would be to trust to the size and strength of these castings and apply antifouling. But as usual we had to go the extra mile(s). We already had a good relationship with Jays Foundry in Norwich and knew their pattern maker Stan Comley - no better anywhere. Although officially retired he took on a lot of pattern making for us. Jays were keen to perfect techniques for casting Aluminium Bronze in big lumps and between them great things were achieved.

My research led me to get in touch with a wonderful man, Kenneth Scott. He had recently completed a thorough and readable account, following years of research, of the Tormentor wartime base for Landing Craft at Warsash . We became great friends and we were invited to join the emotional last reunion of survivors at Warsash . Now, a few years later, many of these fine people have left us.. We were introduced to both wartime captains of our little ship, now sadly gone. Adventures so fondly remembered. Ken is still going strong towards a century.

M

y good natured husband Angus has given all his funds, both financial and efforts, towards a project not primarily of his own choice. He supervised all metalwork restoration and kept life at home from collapsing. After the first months of giving responsibility to contract boatbuilders I decided to run the boatyard myself. I became

aware of a desire to be in control even though I still needed to know a lot about woodworking.

Previous experience building model aeroplanes and re-roofing a house both very useful! Bearded boatbuilders often failed to conceal scorn but in the most part we got along well and I learned everything I now know from them.

There used to be times when the long drive home at the end of the day seemed too much. I would go out to buy a snack supper and sleep on a camp bed in the office.

Walking around the silent boatshed there was a strong feeling of warmth which surrounded Ginger-Dot. I felt like a chick under a mother hen! Nothing bad could happen

there.

But the work , never properly anticipated, has been financially ruinous, as with so many other idealistic and praiseworthy projects. I have always enjoyed everything except bank statements.

With millions being spent on huge superyachts shouldn't there be a tax going into a fund specifically to help support those who try against all odds to stop historical boats being lost forever. . Is sentiment also being lost?

People say "you're getting old, aren't you sick of this ruinous project?" But the feeling is just like sending mother to a nursing home. Worse because she continues to be somehow very interesting and rewarding. It is the challenge to keep her safe that never leaves me. Also I really enjoy scheming the ways to tackle each job. Energy and will are not a problem. But nothing much can happen without serious funding.

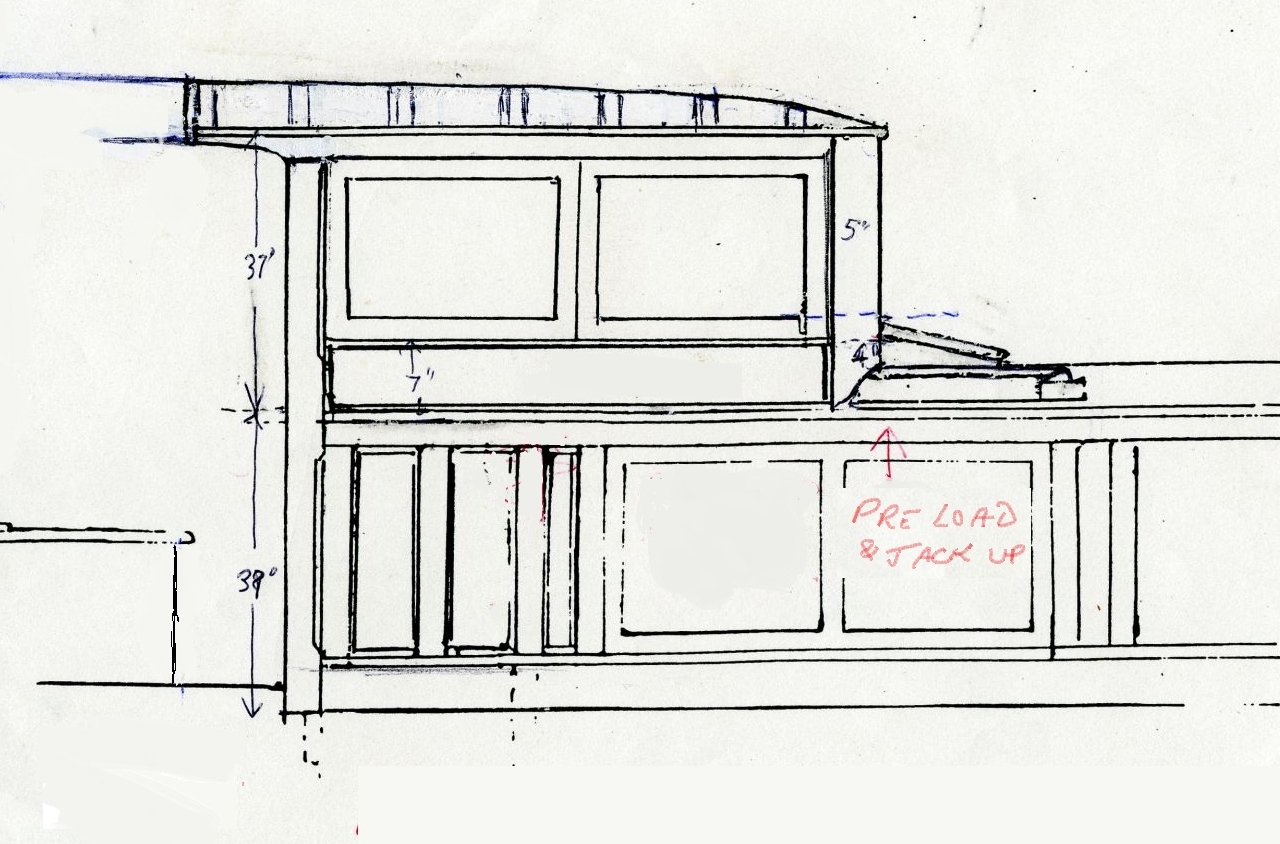

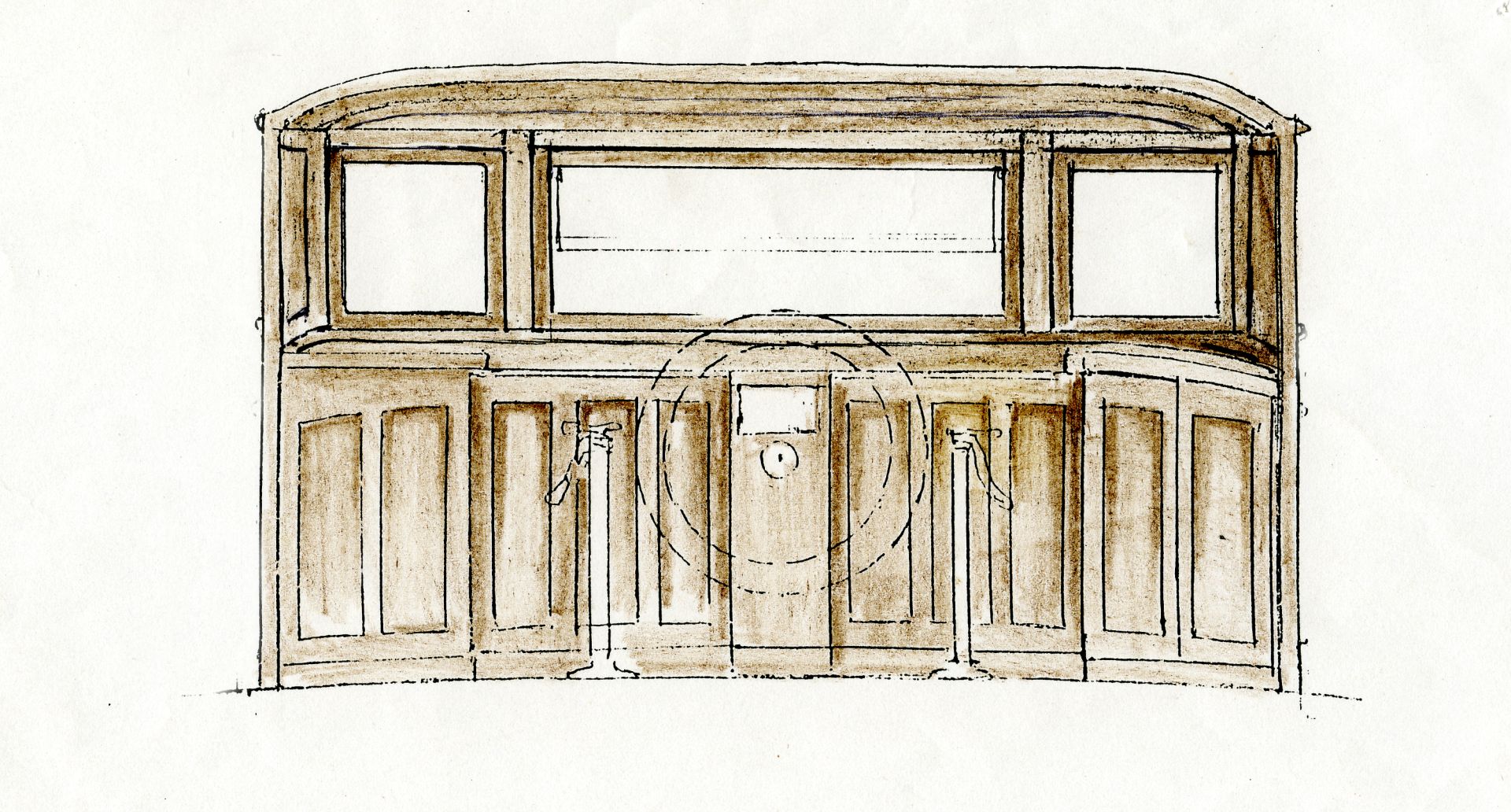

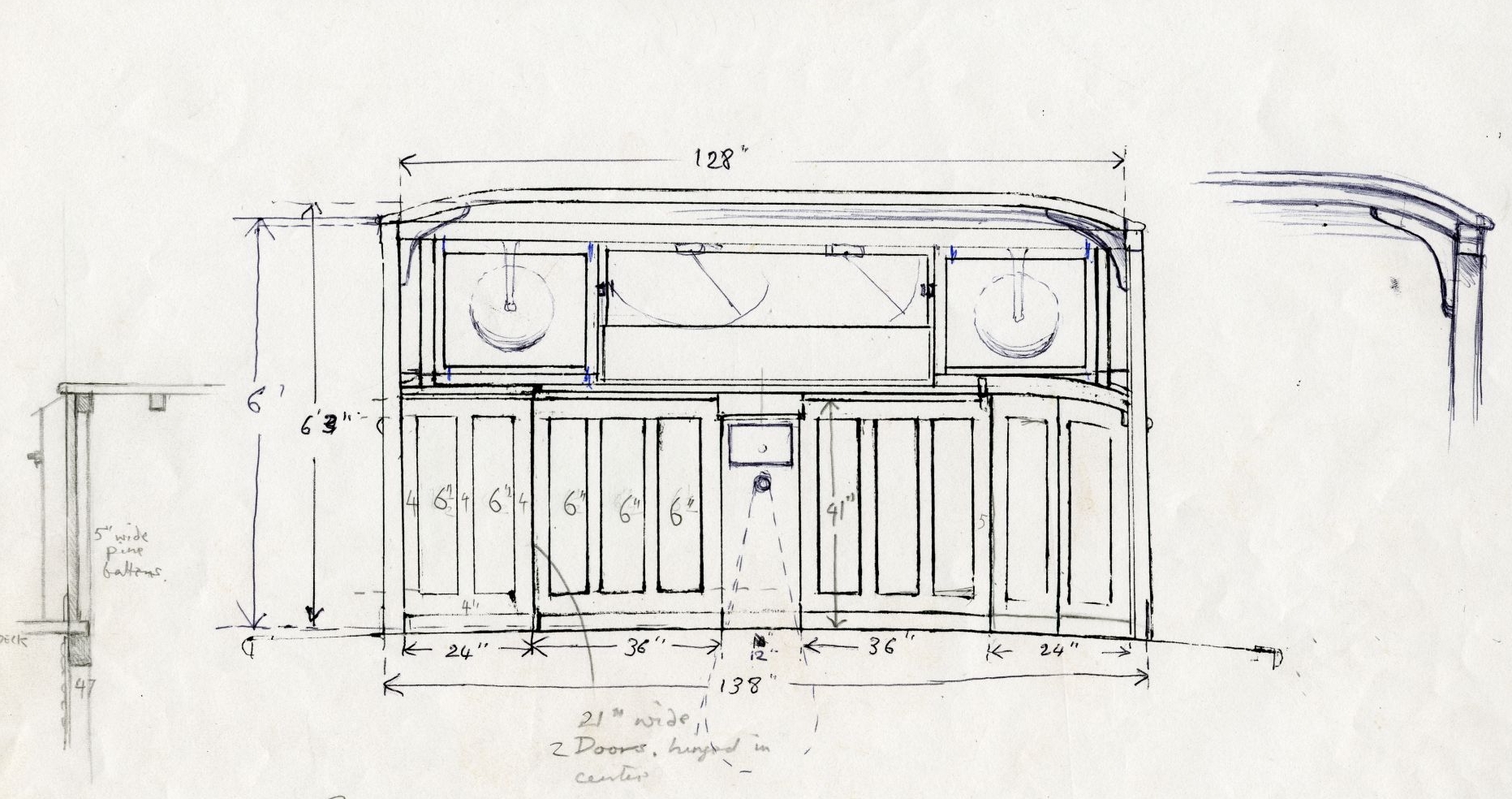

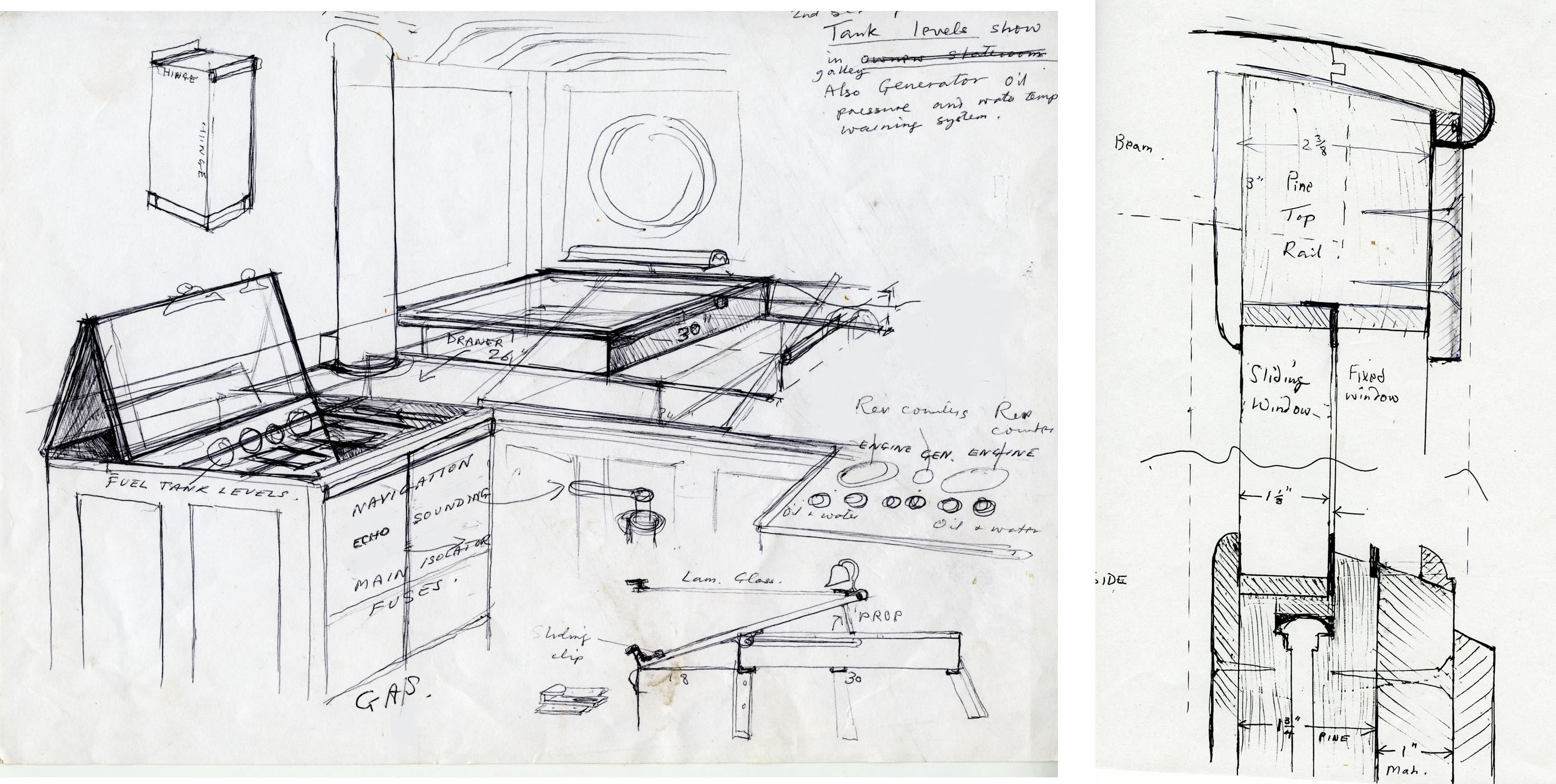

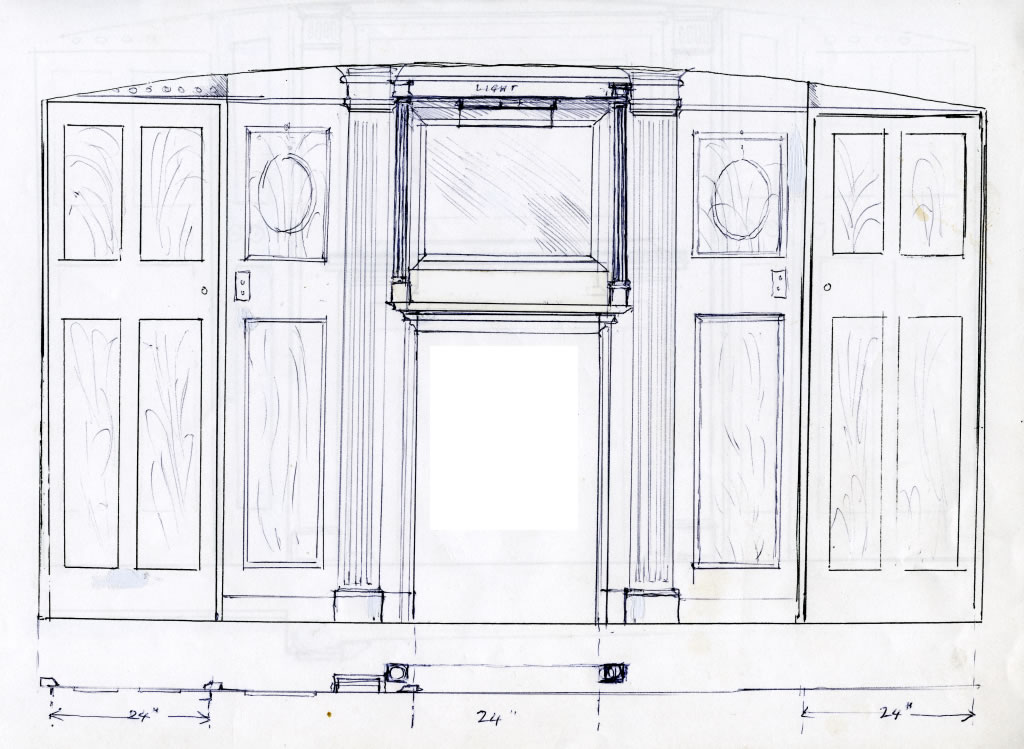

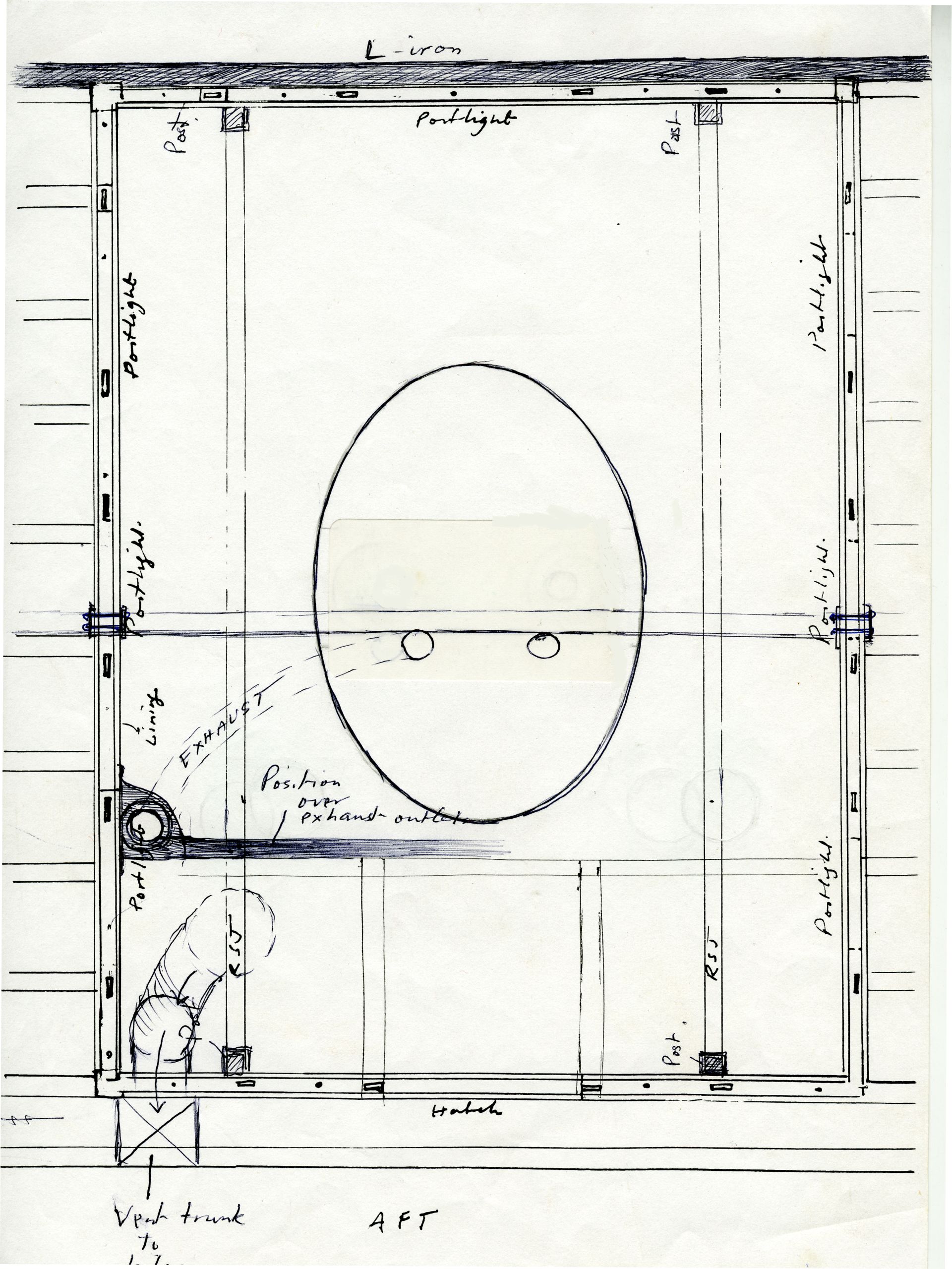

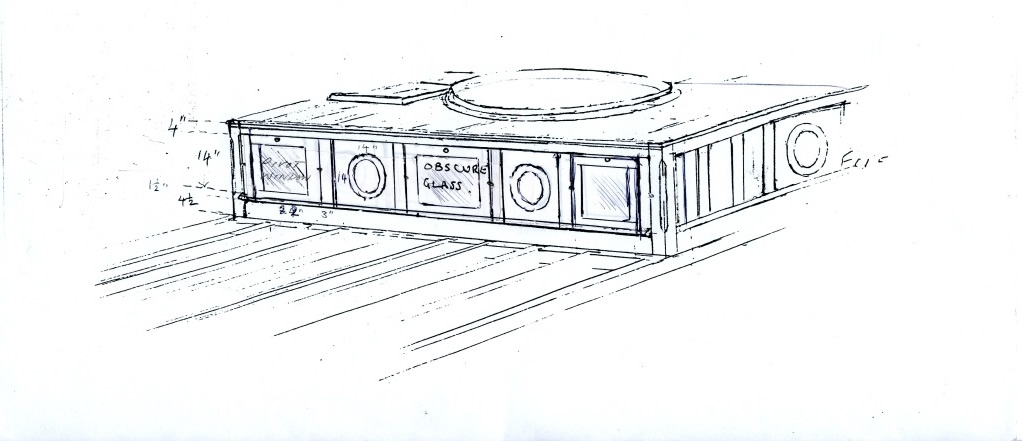

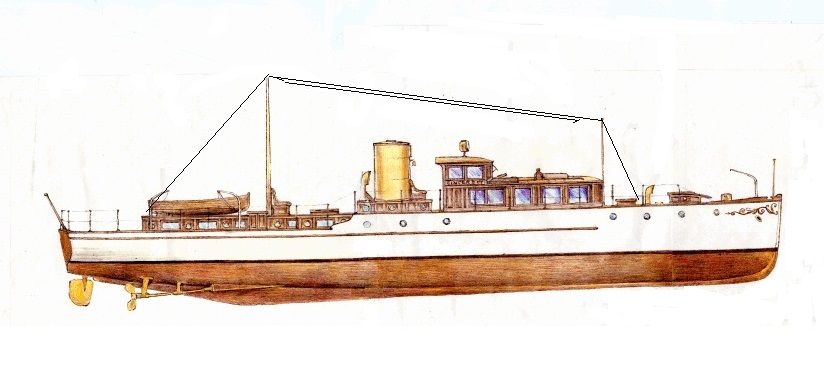

The wheelhouse was built from scaled up drawings from old photographs